3D-printed Surgical Devices and Porous-based Implants For Optimal Bone Integration

KEY INFORMATION

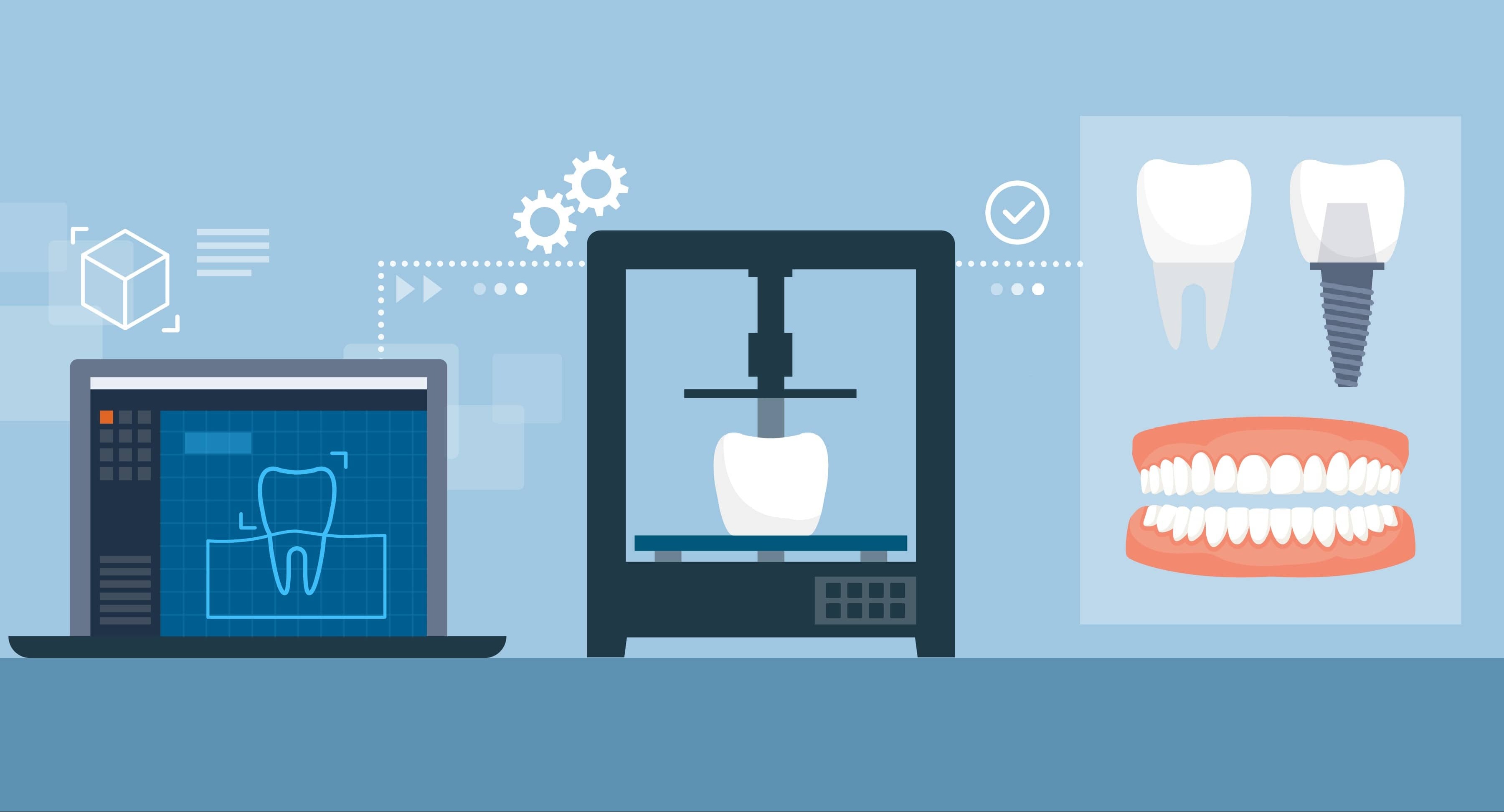

Manufacturing - Additive Manufacturing

TECHNOLOGY OVERVIEW

This cutting-edge technology is setting new benchmarks in global healthcare with its focus on precision and personalized surgical devices and porous-based implants, particularly within the domain of oral and maxillofacial procedures. One of the primary challenges in contemporary surgical treatments has been the pervasive reliance on standardized devices. Such generic solutions often lead to prolonged surgical durations and extended recovery periods.

In contrast, this innovative technology offers a resounding solution by providing 3D-printed surgical devices meticulously tailored to fit individual bone anatomies. The hallmark of these devices lies in their enhanced porous design, which significantly accelerates bone ingrowth and thus curtails healing times. Drawing from extensive clinical evidence, these devices have consistently demonstrated marked improvements in surgical outcomes.

The underlying prowess of this technology hinges on advanced design principles and state-of-the-art manufacturing processes. By implementing a two-scale porous-based topology optimization approach, these medical devices are engineered to ensure anatomical conformity, robust mechanical stability, and optimal biological compatibility.

As a result, they not only promote accelerated bone ingrowth but also ensure the mechanical integrity and longevity of the device. Poised at the crossroads of design excellence and medical proficiency, this technology is on track to redefine global healthcare standards.

TECHNOLOGY FEATURES & SPECIFICATIONS

At the heart of this advanced medical solution lies an array of technical features designed for the modern surgical landscape:

- Personalized Design: The technology employs 3D remodeling and bone segmentation to generate medical devices tailored to individual bone anatomies. This ensures a perfect fit and reduces complications arising from mismatches.

- Two-Scale Porous-Based Topology Optimization: A notable design feature is the use of a two-scale porous-based topology optimization, ensuring devices maintain a balance between anatomical conformity, mechanical stability, and biological compatibility.

- Material Excellence: The devices are manufactured from biocompatible 3D-printed Titanium alloys. This material choice assures durability while conforming seamlessly to the patient's anatomy.

- Enhanced Osseointegration: The devices exhibit a meticulously crafted porous architecture. This design accelerates bone ingrowth without compromising the device's mechanical strength, promoting rapid post-surgery recovery and tissue stability.

- Comprehensive Surgical Solutions: The suite of tools includes cutting guides for precise tumor removal and patient- specific plates for impeccable facial contouring.

- Automated Design System: The creation of the devices is supported by an automated design system, which is proficient in 3D remodeling, bone segmentation, and swift device design, ensuring scalability and patient-centric solutions.

- High Mechanical Integrity: Leveraging advanced additive manufacturing processes, the technology can virtually validate the mechanical integrity and dimensional accuracy of the printed devices, thereby ensuring their long-term reliability in clinical settings.

POTENTIAL APPLICATIONS

This state-of-the-art technology holds transformative potential across a spectrum of surgical and healthcare environments, fundamentally reshaping the approach to personalized medical treatments:

- Oral, Maxillofacial and Dental Surgeries: At the forefront of its applications is the enhancement of oral and maxillofacial procedures. The technology aids in surgeries from mandible reconstructions and orthognathic surgeries to chin adjustments and porous-based dental implants, enabling superior patient outcomes.

- Tumor Removal: With specialized cutting guides, precise tumor excisions are facilitated, increasing the efficiency and accuracy of oncological treatments.

- Facial Contouring: The meticulously designed patient-specific plates, made from high-grade titanium alloys, deliver unparalleled results in facial contouring surgeries, granting patients improved facial symmetry and aesthetics post- operation.

- Orthopedic and Specialized Surgeries: This technology is versatile enough to cater to a range of intricate operations, including spinal screw drilling guides, ankle rotation devices tailored for diabetic patients, and sacral reconstructions.

- Complex Surgical Planning: Local hospitals, even those that might not traditionally have access to advanced equipment, can now offer more complex surgeries. The precision tools and pre-planned approach allow medical facilities to undertake challenging surgical procedures with increased confidence and predictability.

Market Trends & Opportunities

The 3D printed implants and medical device industry is poised for significant growth, reflecting the burgeoning demand in healthcare and dentistry sectors. The global oral and dental services market, currently valued at $302.7 billion in 2022, is predicted to skyrocket to a staggering $497.2 billion by 2028 (Grand View Research). This robust growth is propelled by several intertwined trends: the rise of an aging society, a universal shift towards precision medicine, and heightened awareness about health and hygiene. Moreover, the increasing prevalence of dental and periodontal diseases underscores the imperative for advanced medical solutions.

Technological advancements in dentistry, combined with a growing appetite for cosmetic dentistry and preventive care, have further catalyzed market expansion. Within this vast landscape, the oral and dental 3D printing segment stands out prominently, valued at $3.2 billion in 2022 and projected to nearly triple by 2027. Factors accentuating this explosive growth include the rapidity, precision, and reduced labor intensity of dental 3D printing processes.

Furthermore, the Asia Pacific region is emerging as a pivotal player in this upswing, forecasted to grow at a compelling CAGR of 22.6%. This region's surge is attributed to the rising demand for digital oral and dental solutions and an uptick in dental tourism. Notably, this market potential estimation exclusively considers maxillofacial and orthognathic solutions, leaving room for even more expansive growth when considering porous dental implants, another sector with a booming forecast (7.6% CAGR between 2022-28).

Unique Value Proposition

Leveraging the capabilities of 3D printing, this technology offers medical devices that set a new benchmark in precision and personalization. Central to its innovation is the porous-based structure of the devices, which promotes better integration with surrounding tissues and optimized healing post-surgery. This distinctive feature ensures that each device, tailored to individual anatomical needs, surpasses the general fit and functionality that traditional methods achieve.

Constructed from high-grade materials like titanium alloys, these 3D printed devices not only promise durability but also the benefits of porous designs, ensuring improved patient outcomes. The blend of 3D printing and porous structure also enhances the versatility of applications, from oral surgeries to orthopedic procedures. Moreover, it democratizes access to high-quality healthcare. Medical facilities of any scale can harness this technology, broadening their service offerings and delivering unparalleled patient care. The technology's hallmark lies in its synthesis of 3D-printed precision, porous-based design, and expansive applicability, distinguishing it significantly from conventional solutions.