Autonomous Neuromorphic Vision System for Surface Defect Detection

KEY INFORMATION

Electronics - Sensors & Instrumentation

TECHNOLOGY OVERVIEW

Monitoring for product or part surface defects and anomalies such as cracks and chips throughout the manufacturing process is vital for product quality assurance and control. Traditional inspection or machine vision systems often struggle with complex and nonlinear defect patterns, leading to false positives and missed defects. Deep Learning AI-based detection methods, particularly those using deep neural networks (DNNs), typically require a sufficiently large amount of labelled training data to be effective. However, gathering and labelling such data can be time-consuming and costly, especially for rare or specialized defects.

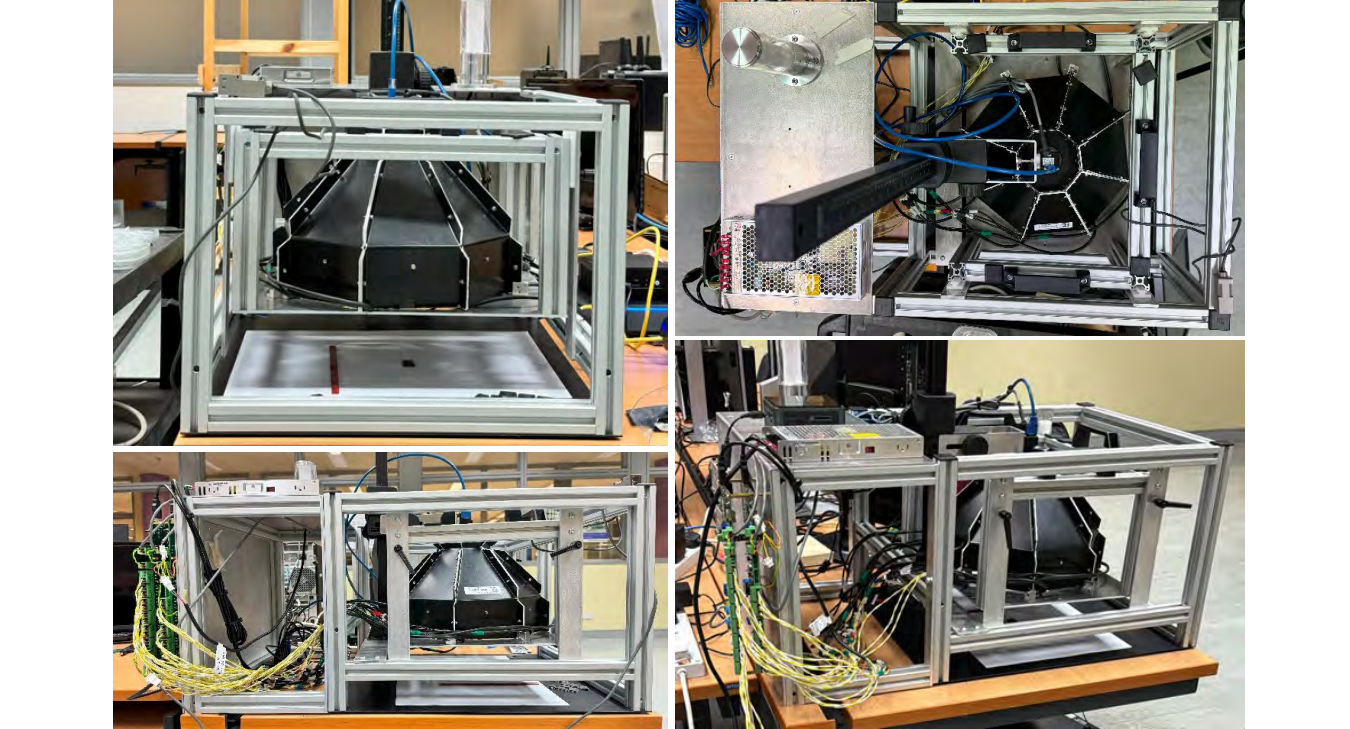

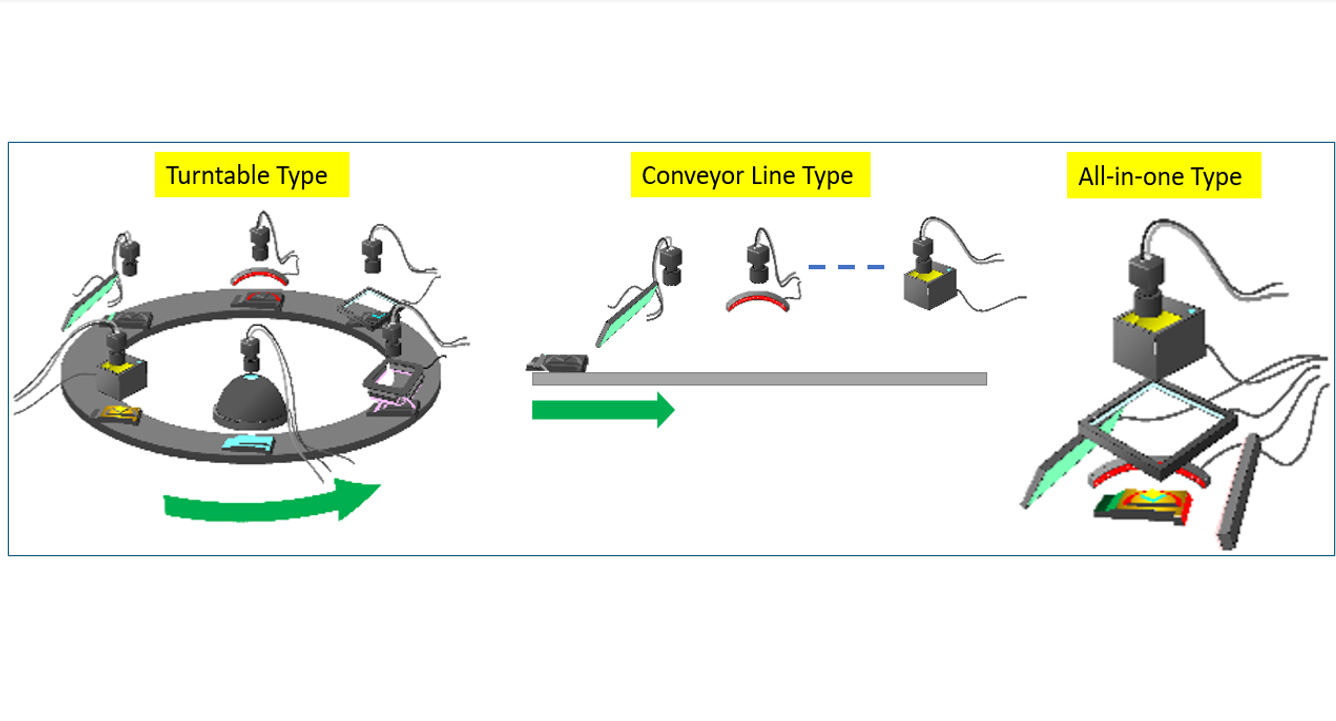

The technology owner has developed a cost-effective system solution leveraging on neuromorphic AI to utilise the principles of human cognitive memory with machine learning to detect surface defects and classifies them reliably and accurately. The system solution includes their patent-pending neuromorphic AI framework architecture with complementary hardware modules, patented lighting system and proprietary software platform. Through the use of neuromorphic edge-AI chip, the proprietary AI model requires smaller training dataset supported incremental learning capabilities, resulting in a high precision, high accuracy system overtime. As the system is camera agnostic and customisable, it enables easy integration and retrofitting to various industrial applications.

There are currently a few ongoing POC projects with industrial partners for automating and enhancing quality checks within their manufacturing line. They are seeking industrial collaboration opportunities who are open to explore surface defect detection for quality assurance or monitoring applications.

TECHNOLOGY FEATURES & SPECIFICATIONS

The technology system solution includes:

- Licensed neuromorphic AI chip with 5508 neurons for edge-AI computing

- Neuromorphic vision module using their patent pending neuromorphic AI framework architecture

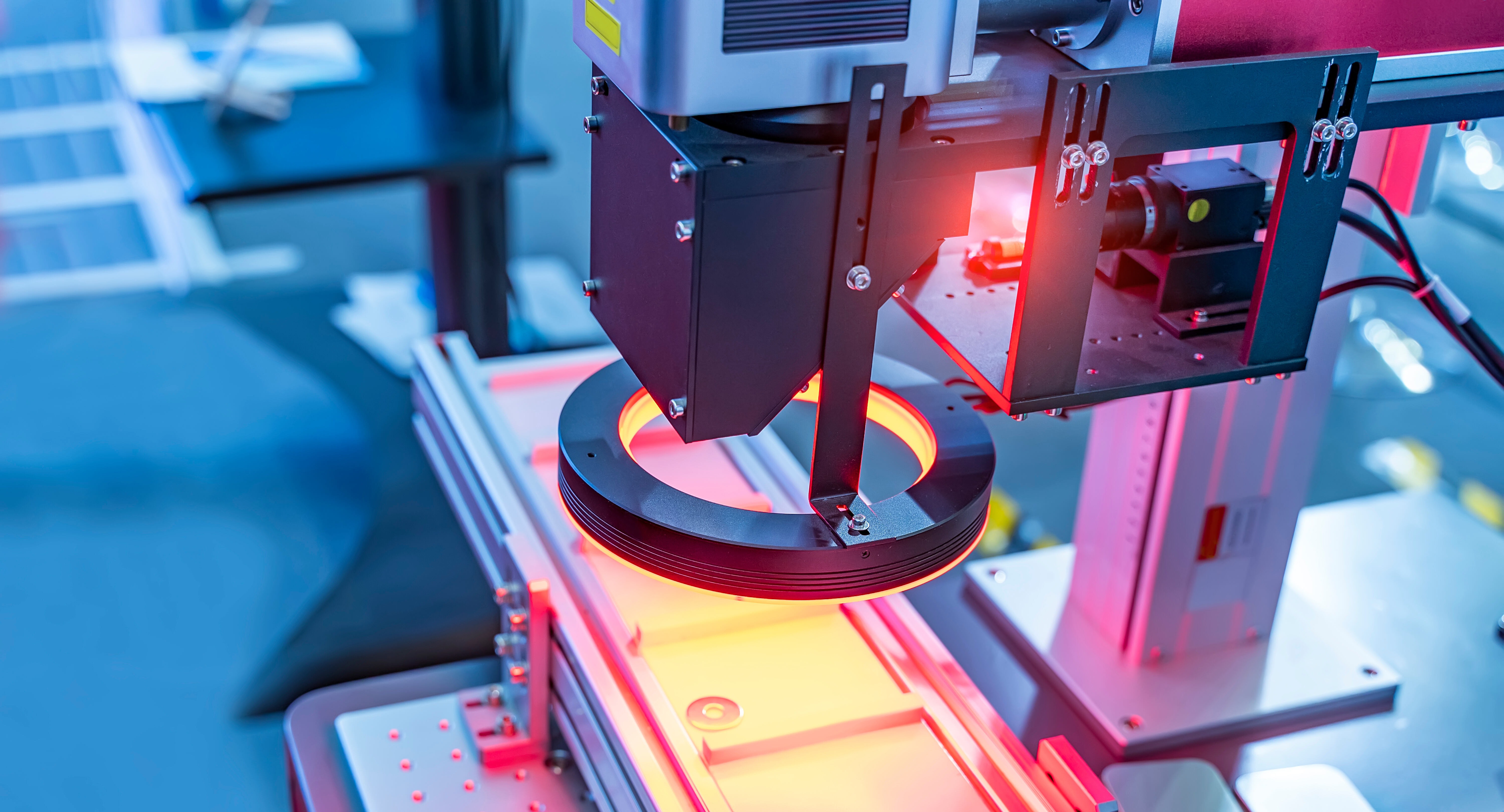

- Patented programmable LED lighting system for accentuating surface defects

- Proprietary image pre-processing AI algorithm and software library

- Proprietary software platform

With the above components, the system solution has the capabilities to do the following:

- Edge-AI computing capabilities

- Identification of complex and nonlinear surface defect detection (such as chip and crack) even with high reflectivity and transparency

- Require smaller (10 to 20) dataset for training, hence reducing training time

- High accuracy rate of up to 95%

- Incremental learning capabilities to further improve accuracy and identification

POTENTIAL APPLICATIONS

Quality Assurance (QA) Inspection: The technology solution is able to autonomous detect surface defects for products for QA checks in industries that require low tolerance in product quality, such as advanced manufacturing. With the system being adaptable to different lighting condition, the technology solution can be integrated along any production processes.

Other Modes of QA Inspection: The technology system is adaptable to other inputs for QA inspections (e.g. x-ray imaging, acoustics) to accommodate for a larger variety of products for quality inspection.

Equipment Condition Monitoring for Predictive Maintenance: The technology solution is able to adaptively learn operating condition status of equipment (e.g. anomaly vibration and acoustics, temperature) to execute predictive maintenance.

Security and Surveillance Application: Facial-based and biometrics for security access control and surveillance ensures computing and storage is on the edge, providing security and tamper-proof.

Unique Value Proposition

The technology system solution enables integration of an autonomous surface defect detection into any production line as a quality assurance solution. Being a customisable solution requiring only a much smaller dataset, the technology solution can easily be integrated with little downtime. By leveraging on their patent-pending neuromorphic AI framework architecture, patented lighting system and proprietary software platform, it enables the use of neuromorphic AI chips for edge-AI applications, provide incremental learning capabilities for enhanced accuracy and overcomes transparency and reflectivity issues in conventional machine vision.