Edible Plant Protein Scaffolds For Cultivated Meat Production

KEY INFORMATION

TECHNOLOGY OVERVIEW

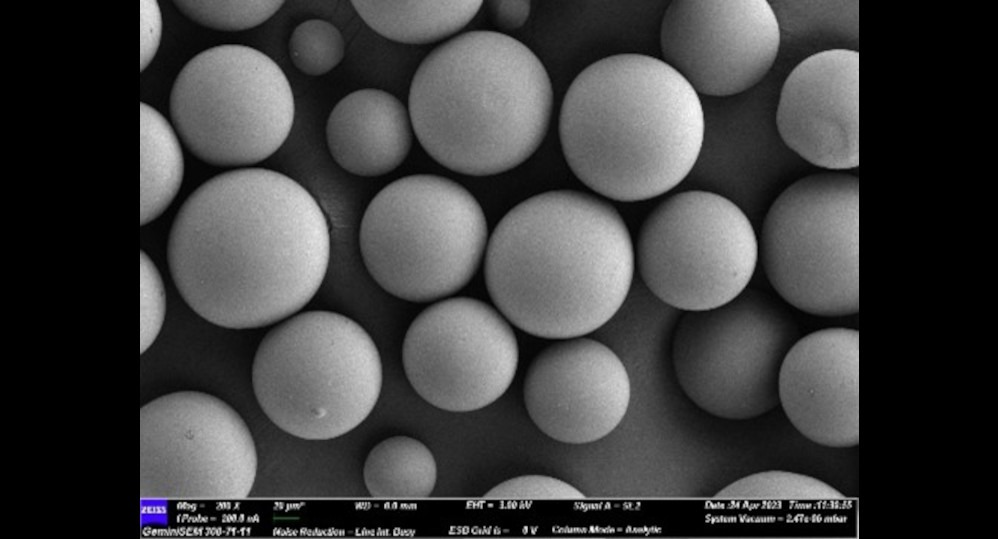

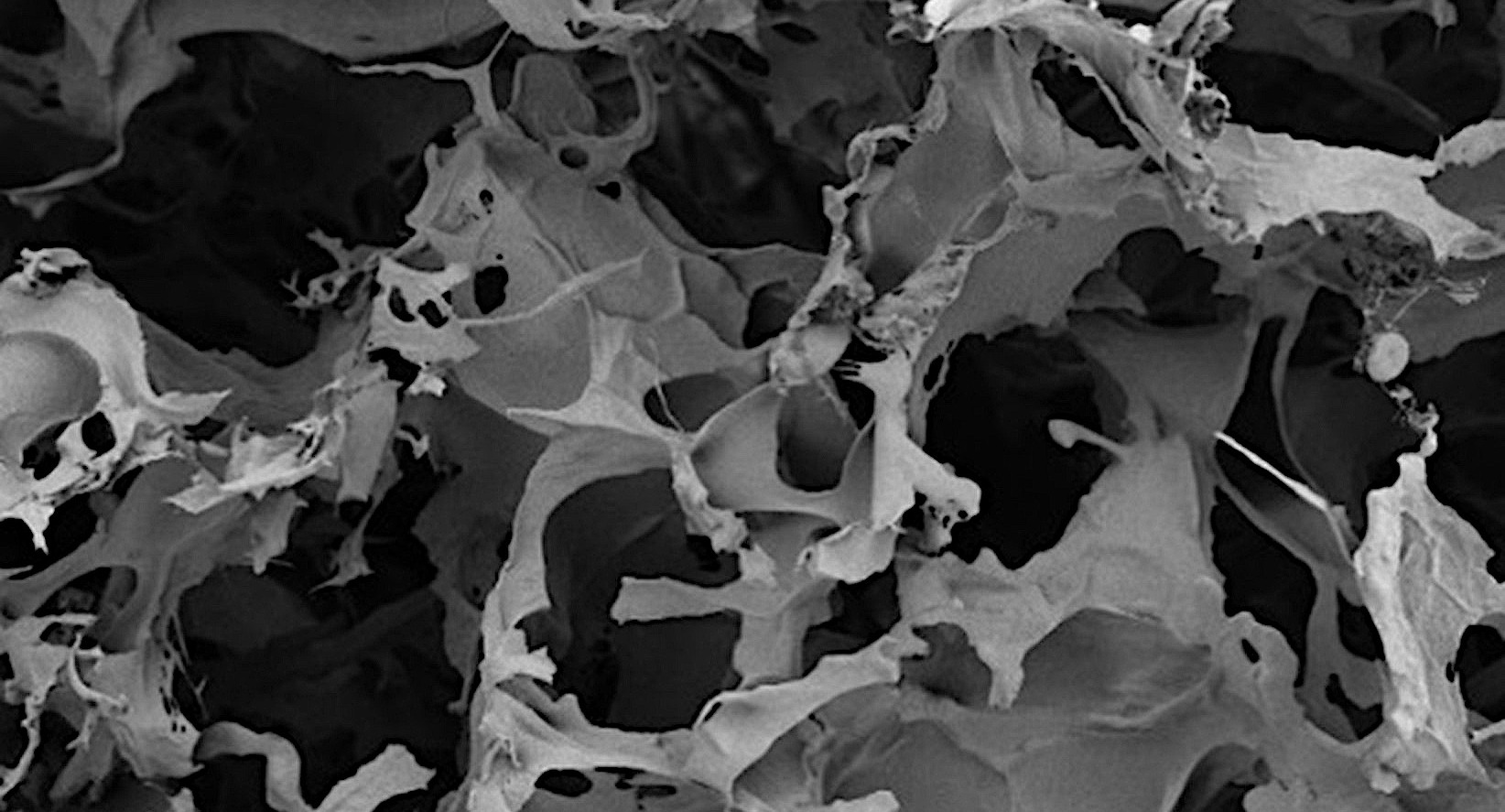

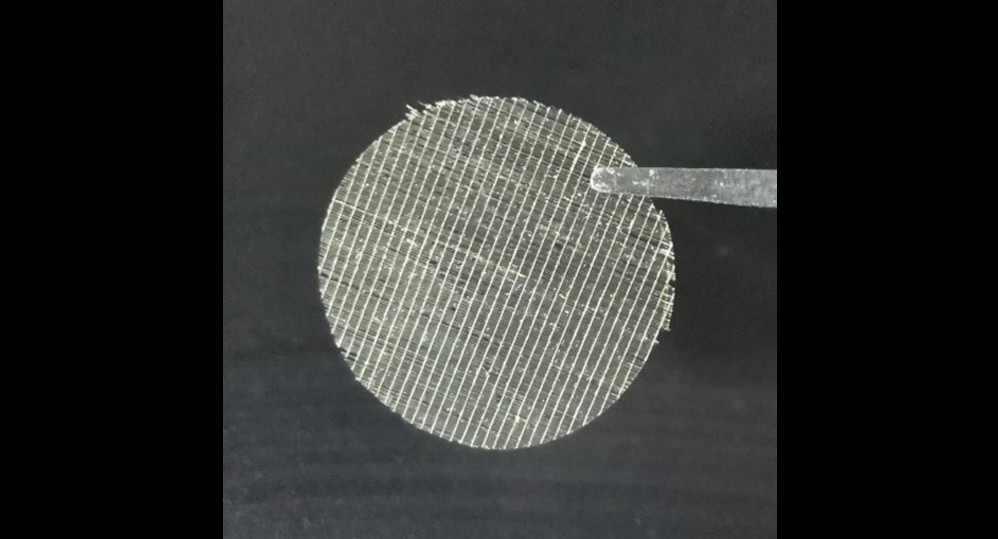

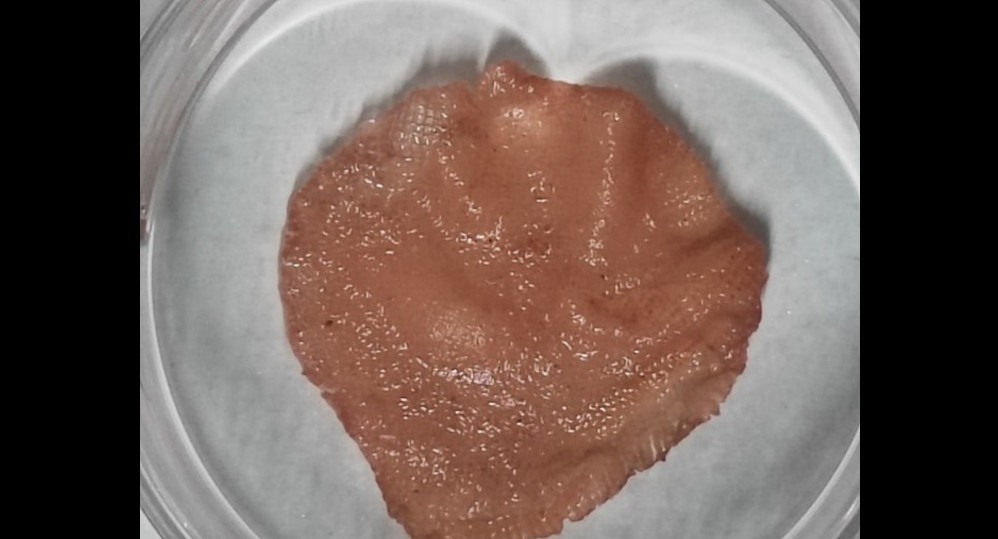

Cultured meat has been hailed as a sustainable future meat production technology, which requires edible and scalable scaffolds to support cell growth. Plant proteins are the most promising raw materials for edible scaffolds but remain underutilized. This technology involves the use of proteins from various grains to produce porous scaffolds and microbeads for cultured meat application. The scaffolds and microbeads could be easily developed with superior properties suitable for cell growth. The plant protein scaffolds and microbeads demonstrate promising potential in providing nutritional value and unique textural characteristics, highlighting the viability of cereal prolamin in promoting cultured meat production.

TECHNOLOGY FEATURES & SPECIFICATIONS

The scaffolds and microbeads can be used for cultured meat producers to support animal cell growth. Since the raw materials and fabrication processes are food-grade, they can be seamlessly integrated into the final meat product without the need for an additional cell-detachment process. Materials are also protein-based, which contributes to the total protein content of the end-product.

Materials used for scaffolds and microbeads

- Zein from corn

- Hordein from barley

- Secalin from rye

- Kafirin from sorghum.

The scaffolds and microbeads have been tested on and shown healthy growth of:

- Porcine satellite cells

- Adipose-derived mesenchymal stem cells

- Bovine satellite cells

- Chicken satellite cells

Performance of the microcarriers tested in a spinner flask bioreactor were comparable in doubling time and adhesion rate to commercially available microcarriers (values for commercially available microcarriers obtained from literature). Scaffolds also resulted in increased integrin expression and differentiation of myoblast cell lines.

POTENTIAL APPLICATIONS

The edible plant protein-based scaffolds and microbeads can be used for cultivated meat production by supporting cell growth and maturation. These microbeads and scaffolds also will impart the end-product with desirable food-related characteristics, such as improved texture and flavour, as well as nutritional value in the form of increased protein content.

Unique Value Proposition

The current methods for in-vitro animal cell expansion typically use suspension cell culture without carriers or rely on plastic carriers, both of which can be expensive and labor-intensive. Edible scaffolds and microbeads made from plant proteins offer a cost-effective alternative by supporting cell growth and allowing seamless integration into the final product. In addition, the microbeads and scaffolds made from cereal prolamins are water-insoluble with favorable cyto-affinities. Thus, they do not require extra crosslinking or specific coating to improve their water stability and cyto-affinities. Besides, cereal proteins can be reclaimed from by-products of the food industry, making the fabrication process both sustainable and scalable.