AI-enabled 3D Spatial Platform for Efficient Facilities Management

KEY INFORMATION

Infocomm - Smart Cities

TECHNOLOGY OVERVIEW

Traditionally, the construction industry has managed information flow through documents and drawings from the design phase to building maintenance, but this information has often been fragmented and not centrally organized. With the rise of digital technology, Building Information Modelling (BIM) has become more widely used, enabling comprehensive management of building lifecycles. However, generation of Digital Twins remains a complex task. The process requires expensive 3D scanning equipment, specialized software, and skilled personnel to process the data. Many companies struggle to fully utilize advanced 3D technologies like BIM and Digital Twins due to these barriers.

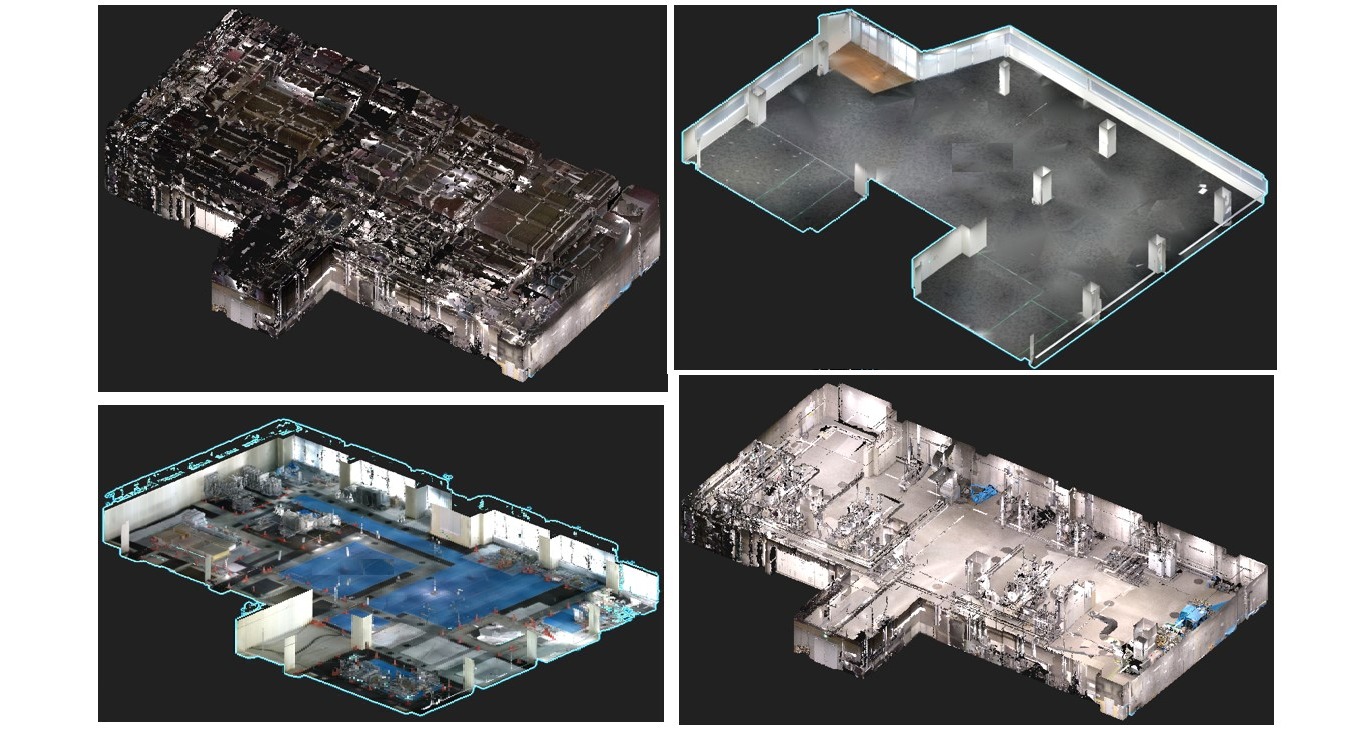

The technology owner has developed an AI powered 3D spatial platform solution that simplifies the creation of Digital Twins and integrates AI technologies to enhance on-site operations. Through the integration of proprietary AI algorithms, it enables the smart generation of the Digital Twins from either their proprietary or third-party scanning solutions and unlocks various AI capabilities utilising the 3D model that even less experienced team members are able to fully leverage on, driving operational efficiency. With the "Conversational AI" capability, it enables the documentation of drawings and reports within the 3D spatial model for easy referencing to facilitate problem-solving through dialogue. The "Asset Detection AI" and “Anomaly Detection AI” capabilities not only automatically detect and map fixed assets onto the Digital Twin and provide an automated ledger generation from it, but also have the function to identify issues (such as cracks or rust) and pinpoint them accurately within the model for prompt action.

TECHNOLOGY FEATURES & SPECIFICATIONS

This solution employs its proprietary imaging devices or compatible third-party scanning solutions for point cloud data acquisition, which is then processed through proprietary AI technology within the digital platform solution to generate the Digital Twin, simplifying the construction process. The key features include:

- Automated alignment of point clouds (creating a unified point cloud dataset)

- Automatic overlay of spherical images onto the mesh generated from the unified point cloud

- Segmentation and categorization of objects using point cloud recognition

- Automatic generation of BIM data from recognized point clouds

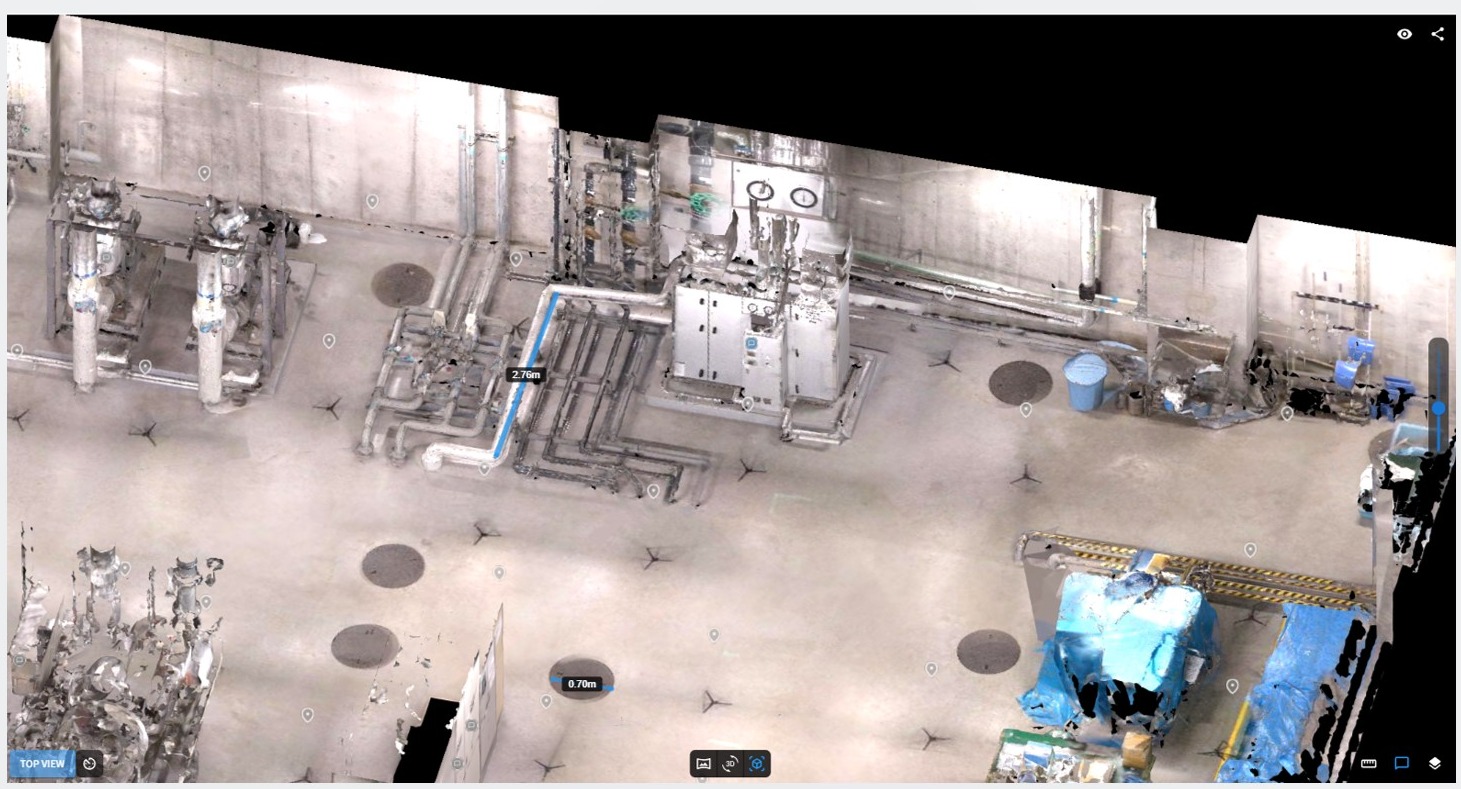

- 3D viewer accessible via web browser for easy visualization

Once the 3D spatial model is generated within the 3D viewer platform, the below AI-powered features can be utilised, with further expansions expected in the future:

- Conversational AI capabilities using internal document data (leveraging Retrieval-Augmented Generation (RAG))

- Visual anomaly detection for rust, cracks, smoke, water leaks, and other infrastructure issues

- Automated ledger generation for detected assets

- On-demand automatic masking to protect privacy (e.g., sensitive labels, personnel)

- Simulation and interference checking for object relocation within the Digital Twin

POTENTIAL APPLICATIONS

Conversational AI Functionality

The multimodal AI, which integrates 3D, imagery, and natural language, extends beyond simple question-answering to more advanced applications. For instance, it can reduce the time spent on document creation by automating report template generation. Furthermore, by recognizing images and point clouds and providing related information (such as hazardous areas), the AI can assist in identifying potential issues that might otherwise go unnoticed through conversational prompts.

Anomaly Detection AI Functionality

For rust detection, the AI can assess the severity of anomalies using characteristics like color, texture, and shape. For crack detection, the AI can evaluate the length, width, and depth of continuous cracks through advanced image recognition and depth estimation, providing accurate severity assessments.

By integrating these detection capabilities with the Digital Twin, anomalies can be managed and tracked over time. Moreover, the Conversational AI feature can notify relevant stakeholders when an anomaly reaches a critical level, allowing for proactive management. The AI can also automatically generate reports summarizing detected anomalies, streamlining any maintenance reporting process.

The company is seeking collaborative partners like facilities and infrastructure owners who wish to further develop or empower business operations with AI capabilities to optimize their maintenance workflow and operational capabilities.

Unique Value Proposition

The technology solution easily generates 3D spatial via its own or third-party scanning solutions and is easily accessible via a web platform. With the integration of various state-of-the-art AI software algorithms, it enables interaction of the 3D space, thereby unlocking its full functionalities to non-expertise personnel for other business optimisation. Its proprietary anomaly detection AI empowers enterprises to accurately track and prioritise abnormalities on their equipment, enhancing maintenance operations and reducing unexpected downtime.