Smart Soft Robotic Gripper for Delicate, Heterogenous Objects

KEY INFORMATION

Foods - Processes

TECHNOLOGY OVERVIEW

With the global trend of industrial automation, robotic arm technology is being developed and integrated to existing business workflow, increasing labour productivity and operational efficiency. However, current end effectors attached to robotic arm excels in automation tasks of handling homogeneous robust objects but fall short in handling irregular, fragile objects. Current robotic grippers (end effector) lack the finesse and limberness required, limiting their usage in particular areas such as agriculture, F&B, pharmaceutical and logistics.

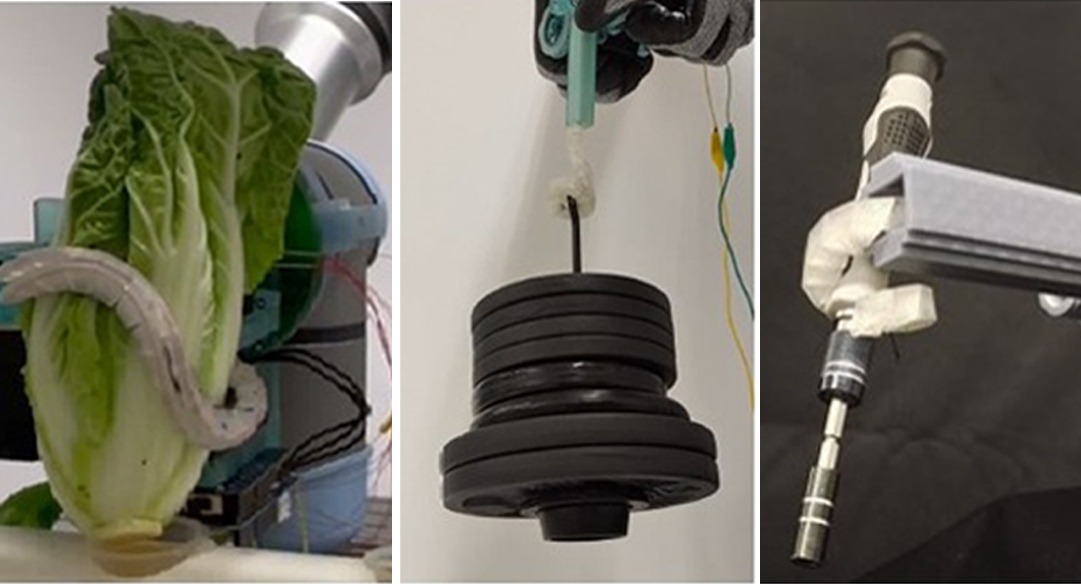

The technology solution developed is a smart soft robotic gripper as a modular end effector that addresses the challenge of handling objects with varying sizes, shapes, and weights, an issue unsolved by traditional robotic grippers. This innovative gripper tool mimics the flexibility and versatility of biological structures like tendrils, enabling an extra dimension of growth and twining capabilities. By wrapping itself securely around objects, the gripper manipulates items gently, minimizing the risk of crushing or damaging them. Its integrated sensors provide real-time contact feedback capabilities, enabling precise monitoring and adaptive control by the robotic system.

The technology owner is seeking collaborative partners, such as system integrators or end-users, who are in need and keen to integrate a versatile, adaptive, and gentle handling solution that can operate efficiently in environments where object fragility or irregularity is a key concern.

TECHNOLOGY FEATURES & SPECIFICATIONS

The smart soft robotic gripper module comprises of three key components: flexible fingers, actuation system and sensor integration. A novel concept is introduced for a flexible finger, utilizing a single tendon within a flexible body to perform three-dimensional bending and twisting motions. This design enhances the gripper’s adaptability, allowing it to handle objects with various shapes, sizes, and weights, with current payload exceeding 10kg. The integration of vision and haptic sensors further refines its capabilities to provide gentle and precise manipulation of delicate items. Additionally, the sensor integration supports potential applications in sensor fusion and IoT systems, expanding its utility across advanced automation environments like smart farms and smart factories. With its modular design, it enables customisation and scalability to integrate into existing robotic systems.

POTENTIAL APPLICATIONS

Handling of Food (urban farming, food and beverages)

The gripper solution can gently handle delicate crops like bunches of vegetables and irregularly shaped fruits, which can facilitate automated harvesting or processing with minimal damage. Its adaptability makes it potentially suitable for smart farms where precision and adaptability are essential. A pilot test for harvesting automation is currently being conducted in an urban farming application.

Smart Factories (warehousing, manufacturing)

The gripper solution is able to handle a variety of fragile and odd-shaped product, providing flexibility to environments of heterogenous items. The technology also enables safe handling of items, promoting industrial automation of delicate assemblies and improving assembly precision.

Pharmaceuticals (medical device, procedures)

The gripper tool can handle sensitive medical devices and products to minimise or prevent damaging during handling. The tool is able to provide additional assistance to medical personnel for more delicate medical procedures, reducing discomfort while increasing precision.

Unique Value Proposition

The smart soft robotic gripper is bio-inspired and mimics natural organism, like octopus arms, to enhance navigation and interaction with their surroundings. This results in an extra dimension of flexibility and versatility to handle intrinsic nonlinearity of soft, delicate, heterogenous materials. The integrated sensors enable situational awareness capabilities, providing adaptability and enhancing precision. Lastly, the modular design provides customisability to specific use-cases, with the gripper being able to be scaled to suit the operational needs.