Revolutionizing Machine Health Analysis with AI Solutions

KEY INFORMATION

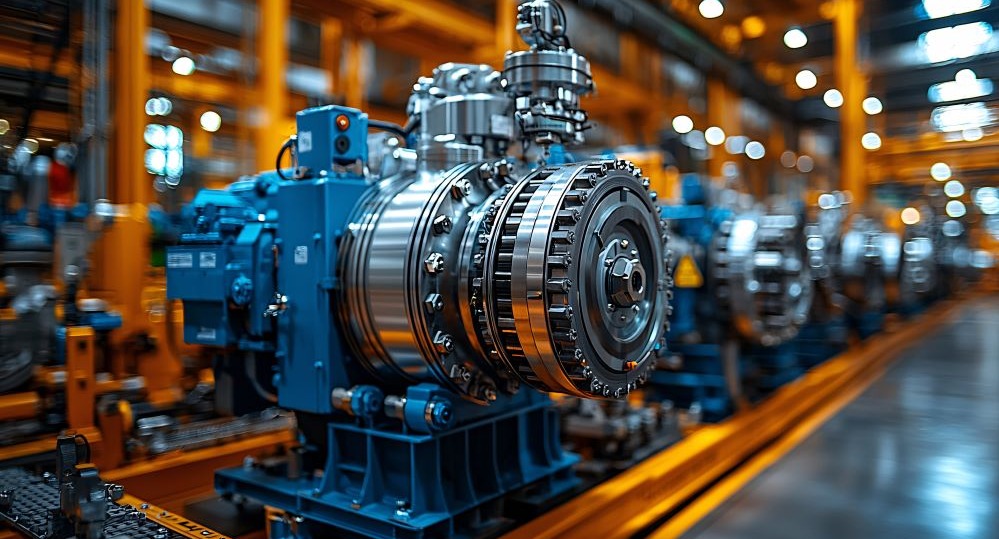

TECHNOLOGY OVERVIEW

The technology redefines equipment monitoring and maintenance with its novel approach and sets itself apart from conventional solutions. Unlike traditional predictive maintenance methods that rely on pre-installed expensive sensors, this solution leverages a robust analysis of existing data, integrating AI and machine learning, to provide accurate health assessments and predictions. Conventional systems often struggle with managing and classifying large volumes of alarm data, leading to delayed response and overlooked issues. In contrast, this system excels in managing large volumes of alarm data, classifying faults and critical alerts, and monitoring emerging trends to address potential issues. The technology also has the capacity to automate the identification of Standard Operating Procedures (SOPs) and to utilize sophisticated AI agents to orchestrate real-time, factory-wide monitoring. This approach addresses several key pain points in the equipment maintenance industry and helps in achieving higher equipment uptimes (Overall Equipment Efficiency, OEE). By focusing on data-driven insights rather than additional sensors, this technology also offers a more cost-effective and flexible approach to equipment health management, ensuring comprehensive and proactive maintenance strategies.

TECHNOLOGY FEATURES & SPECIFICATIONS

- Unsupervised Machine Learning: The solution excels at identifying patterns and anomalies without pre-labeled data, enabling it to analyze and generate insights even without extensive historical data, making it highly adaptable to new situations.

- Data Integration: The platform can seamlessly integrate with any data set, independent of OEM support, ensuring comprehensive monitoring and analysis without requiring prior data preparation or understanding.

- Health Index for Equipment: The solution offers a detailed health index for machinery, providing clear and actionable assessments that inform maintenance decisions and optimize operational efficiency.

- Predictive Maintenance Capability: Equipped with predictive maintenance functionalities, the solution analyzes data trends to forecast potential issues, helping to prevent equipment failures, reduce downtime, and enhance productivity.

- Integrated MLops Platform: The solution includes an MLops framework that manages and monitors machine learning models, ensuring efficient operation, continuous improvement, and scalability of its machine learning components.

POTENTIAL APPLICATIONS

- Semiconductor and Advanced Manufacturing: This solution is ideal for the semiconductor industry and other advanced manufacturing sectors, where precision and reliability are critical. Its advanced monitoring and predictive capabilities ensure equipment operates within optimal parameters, minimizing defects and inefficiencies. By processing large volumes of data in real-time, the system enhances quality control, reduces waste, and improves production yields.

- Predictive Maintenance: The solution revolutionizes predictive maintenance across industries by using data analysis and machine learning to anticipate equipment failures before they occur. This proactive approach enables timely interventions, reducing unexpected breakdowns and extending machinery lifespan. By forecasting issues based on real-time and historical data, the system helps avoid costly downtime and maintains continuous production.

- N+1 Standby Reduction: In N+1 manufacturing environments, the solution optimizes energy consumption by minimizing the need for standby equipment. Traditionally, equipment must be kept on standby, leading to unnecessary energy use and higher costs. The solution provides real-time insights into equipment health, allowing for more efficient standby management. This reduces energy consumption and operational costs, contributing to substantial energy savings and a lower environmental impact.

Unique Value Proposition

- No Need for Equipment Sensoring: This solution bypasses the need for extensive sensor networks, reducing costs and logistical challenges associated with sensor installation and maintenance.

- Minimal Dependence on Large Data Sets: It does not rely on large volumes of historical data, making it more adaptable and less data-intensive, which reduces the time and resources needed for data gathering and processing.

- Actionable Intelligence On-Site: The solution provides localized insights directly at the equipment site, enabling faster response times and immediate adjustments without the need for centralized data processing.

- Data-Driven Insights Without Negative Data Reliance: Focused on current operational data rather than past failures, the solution promotes proactive maintenance strategies, optimizing real-time performance.

- Utilizes Unsupervised Deep Learning: Advanced unsupervised deep learning techniques allow the system to detect complex, previously unknown issues without needing predefined labels or categories.

- Improves Accuracy Over Time with Reinforcement Learning: Incorporating reinforcement learning, the solution continuously enhances its accuracy and predictive capabilities as it processes more data, leading to greater precision over time.