Low-Cost Probiotics Encapsulation for Targeted Release, Improved Viability and Shelf-Life

KEY INFORMATION

Foods - Processes

TECHNOLOGY OVERVIEW

This technology is suitable for companies looking for a probiotics delivery system with increased probiotics viability. Spray-dried probiotic powder derived from this technology can be used as dietary supplements or functional food additives for human and animal consumption.

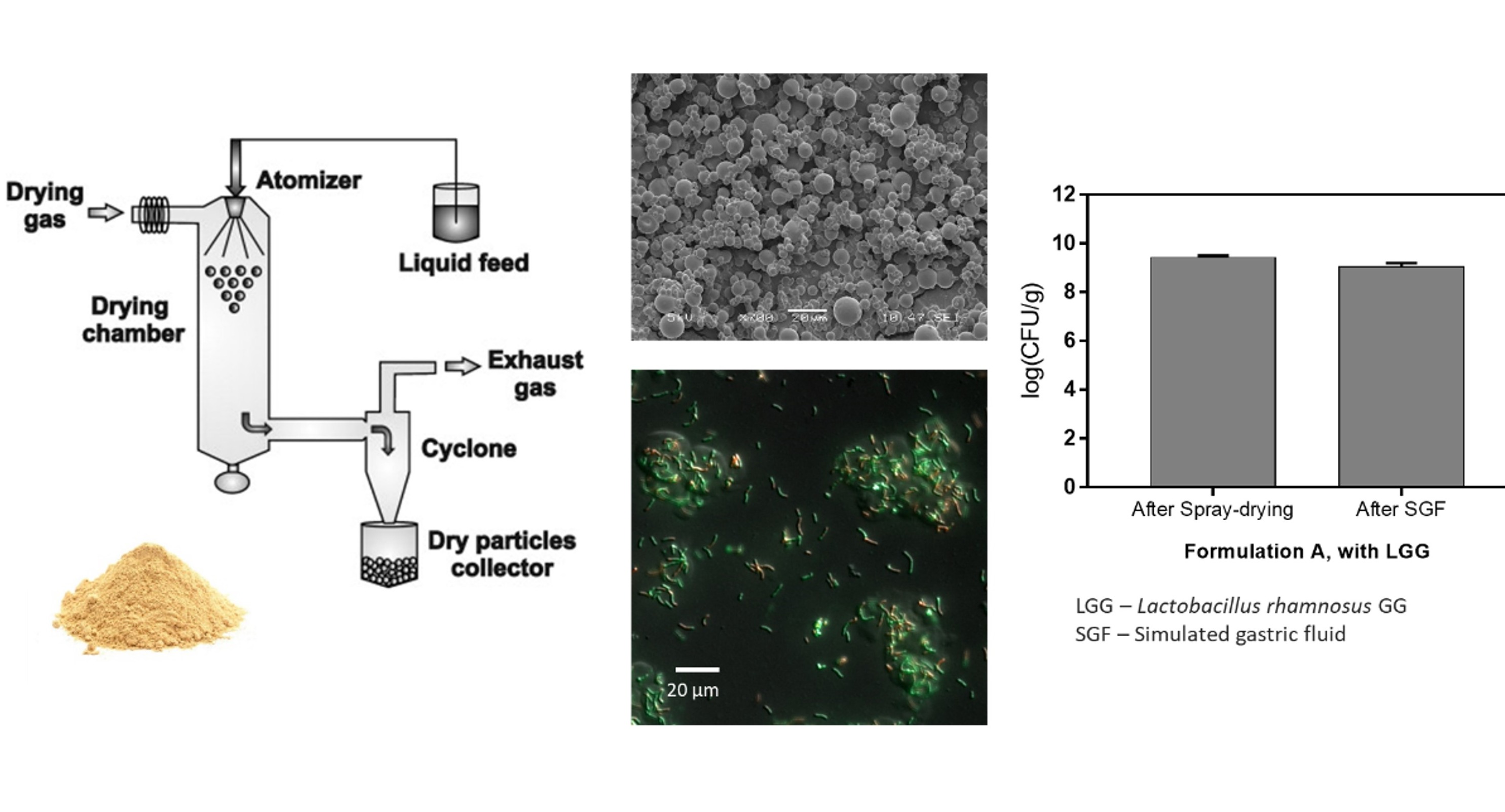

Conventional probiotics often lose viability during shelf storage and upon ingestion, especially during their transit through the gastric region. Our industrially scalable encapsulation technology can improve probiotics’ shelf life and maintain viability during their passage through the human upper gastrointestinal tract. The encapsulated probiotic product achieves qualities of gastroprotection and targeted release in the intestinal region, overall boosting the beneficial effects of probiotics on gut health.

Probiotics represent a US$ 58 billion market with immense growth potential, as global consumers are increasingly invested in digestive health and means to enhance the gut microbiome. Our patented technology of encapsulating probiotics involves a modified spray-drying process and is a high-throughput, food-grade, and inexpensive technique applicable to pharmaceutical, food and animal feed sectors.

TECHNOLOGY FEATURES & SPECIFICATIONS

The modified spray drying technique used in this technology is a facile, high-throughput and industrially preferred method to produce environment resistant encapsulation systems.

Key advantages of this optimized spray drying process include:

- High encapsulation efficiency

- High probiotics viability

- Achieving a dried product with high powder yield

This technology provides four major advantages in probiotics supplementation:

- Scalability of production

- Uses food-grade materials and hence renders the advantage of non-toxicity

- Offers gastroprotection of probiotics in the upper GI tract

- High viability over shelf-life

POTENTIAL APPLICATIONS

This technology may be versatilely used for a variety of candidate probiotic microorganisms and can henceforth be applied to many different applications and markets. The encapsulated dry probiotic powder product is:

1. Applicable to both human health product lines and animal feed formulations due to its use of generally regarded as safe (GRAS), non-toxic materials

2. Compatible with incorporation of other active pharmaceutical ingredients alongside probiotics (to promote or enhance desired therapeutic outcomes)

3. Dried probiotic powder is compatible with standard pharmaceutical or dietary supplement dosage formats (e.g. capsules, tablets, or sachets)

4. Dried probiotic powder can be incorporated into functional food or beverage matrices, such as confectionaries, dairy products and instant foods.

Market Trends & Opportunities

The probiotics market was valued at US$ 58 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 7.5% through 2030. The market is driven by a rise in health expenditure, an increasing consumer inclination towards preventive healthcare and a growing consumer awareness about the importance of the gut microbiome in influencing human health.

So far, probiotics are mainly consumed via dairy-based yogurts (74% of the global retail value of probiotics), while 11% is attributed towards probiotics supplements. The market for probiotic supplements is set to expand rapidly, at a CAGR of 7%, from its market size of US$ 6.5 billion in 2021 (Grand View Research, 2021). Probiotic supplements may be consumed in the form of capsules, chewables/gummies, powders, tablets and softgels. This technology is well-positioned to develop probiotic supplements suitable for these various formats, as the dried powder product can be versatilely incorporated.

Besides supplements, there is a growing trend to incorporate probiotics in different foods and beverages. Several examples of innovation here include probiotic ice-creams, probiotic sodas, probiotic beers, probiotic candies, probiotic ice, etc. This technology can be useful to encapsulate and protect probiotics from the external food or beverage matrix and prolong its survivability and functionality.

The use of probiotics in animal feed sectors represents another opportunity. The global probiotics in the animal feed market was valued at US$ 4.4 billion in 2020 and is projected to grow at a CAGR of 8.8% through 2026. This technology benefits from having a high-scale and inexpensive production process, which reduces the costs of the encapsulation of probiotics.

Unique Value Proposition

Using an industry-approved spray drying technique and food-grade materials, our encapsulation system guarantees both safety and scalability. This advanced technology ensures the probiotics' viability as they pass through the upper gastrointestinal tract and reach the gut, providing a remarkable advantage over conventional probiotics.